- marketing@technosalesindya.com

- +91-9225322743

Screw Driver

Product Range

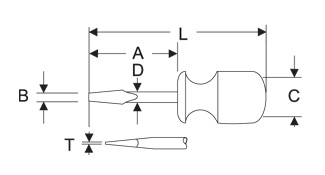

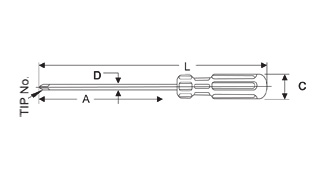

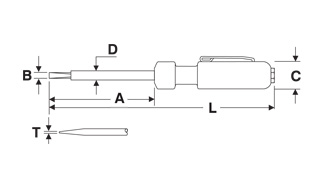

Flat Screw Drivers

The blade is made from high grade Silicon - Manganese steel which no other make uses. This steel gives spring effect also.

The blade is differently hardened and tempered to resist wear, bending and meet high torque requirement. Other makes offer same hardness through out the length of the blade, which is not scientific.

Hardness on tip : 55 to 58 HRC. Other makes offer much less hardness on tip. Higher the hardness higher is wear resistance.

The blade tip is magnetised to lift small screw etc.from confined spaces or to hold the the screw in position.

-

PROD.NO TIP SIZE B x T A C D L WT.GMS 932 0.6 x 0.4 50 13 3.0 110 10 933 1.6 x 0.4 75 13 3.0 135 12 911 3.0 x 0.4 50 13 3.0 110 10 901 3.0 x 0.5 75 17 3.0 150 21 902 3.0 x 0.4 100 17 3.0 175 22 912 3.5 x 0.5 75 14 3.5 140 16 842 3.5 x 0.5 150 17 3.5 225 35 913 4.0 x 0.6 100 18 4.0 18 30 712 4.0 x 0.6 125 17 4.0 200 30 833 4.0 x 0.6 200 18 4.0 280 40 713 5.0 x 0.6 75 18 5.0 155 35 936 5.0 x 0.8 150 22 5.0 236 60 921 6.0 x 0.6 75 22 6.0 161 55 922 6.0 x 6.0 100 22 6.0 186 60 923 6.0 x 0.8 125 22 6.0 211 62 824 6.0 x 0.8 150 22 6.0 236 65 825 6.0 x 0.8 200 22 6.0 286 77 826 6.0 x 0.8 250 22 6.0 336 90 924 8.0 x 1.2 125 28 8.0 230 115 925 8.0 x 1.2 150 28 8.0 255 130 926 8.0 x 1.2 175 28 8.0 280 130 827 8.0 x 1.2 200 28 8.0 305 145 828 8.0 x 1.2 250 28 8.0 355 165 829 8.0 x 1.2 300 28 8.0 405 180 725 10.0 x 1.2 150 26 8.0 248 120 927 10.0 x 1.2 200 34 10.0 327 245 928 10.0 x 1.2 250 34 10.0 377 275 929 10.0 x 1.5 300 34 10.0 427 310 930 10.0 X 1.5 400 34 10.0 527 365 931 13.0 x 1.9 450 34 10.0 577 395

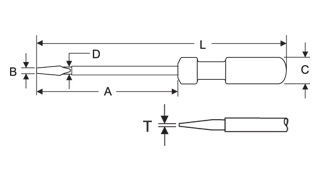

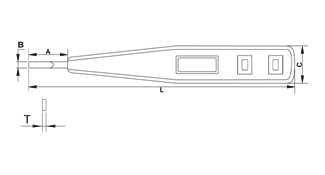

Insulated Screw Drivers

-

PROD.NO TIP SIZE B x T A C D L WT.GMS 822 I 3.5 x 0.5 125 17 3.5 200 30 842 I 3.5 x 0.5 150 17 3.5 225 35 832 I 3.5 x 0.5 200 17 3.5 275 40 823 I 3.4 x 0.6 150 18 4.0 230 40 833 I 4.0 x 0.6 200 18 4.0 280 40 934 I 5.0 x 0.6 100 22 5.0 186 50 935 I 5.0 x 0.6 125 22 5.0 211 55 936 I 5.0 x 0.8 150 22 5.0 236 60 937 I 5.5 x 0.6 200 22 5.0 286 70 938 I 5.0 x 0.8 250 22 5.0 336 80 939 I 5.0 x 0.8 300 22 5.0 386 90 824 I 6.0 x 0.8 150 22 6.0 236 65 825 I 6.0 x 0.8 200 22 6.0 286 77 826 I 6.0 x 0.8 250 22 6.0 336 90 827 I 8.0 x 1.2 200 28 8.0 305 145 829 I 8.0 x 1.2 300 28 8.0 405 180 928 I 10.0 x 1.2 250 34 10.0 377 275

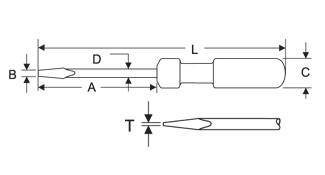

Philips Screw Drivers

-

PROD.NO TIP SIZE B x T A C D L WT.GMS P3 859 50 0 50 13 3 108 15 P3 860 60 0 60 17 3 135 20 P3 860 150 0 150 17 3 225 25 P5 861 75 1 75 22 3 160 50 P5 861 100 1 100 22 5 185 55 P5 861 150 1 150 22 5 235 60 P5 861 200 1 200 22 5 285 65 P6 862 100 2 100 22 6 198 80 P6 862 150 2 150 26 6 248 95 P6 862 200 2 200 26 6 298 110 P6 862 250 2 250 26 6 348 125 P6 862 300 2 300 26 6 398 140 P8 863 150 3 150 28 8 255 155 P8 863 200 3 200 28 8 305 175 P8 863 250 3 250 28 8 355 195 P8 863 300 3 300 28 8 405 215 P1 864 200 4 200 34 10 327 250

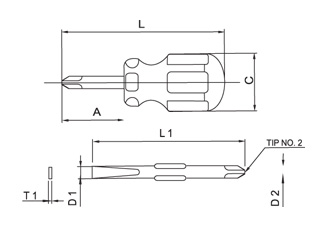

Two-in-one Stubby Screw Drivers

-

PROD.NO A C D L TIP SIZE

D1 x T1TIP SIZE

D2 x T1L1 WT.

GMS974 95 22 6 180 6.0 x 0.8 6.0 x 2 PHILIPS 75 55

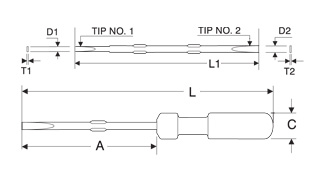

Two-in-one Screw Drivers

-

PROD.NO A C L TIP SIZE

D1 x T1TIP SIZE

D2 x T1L1 WT.

GMS803 55 17 130 3.5 x 0.5 3.5 x 0 PHILIPS 122 25 804 75 18 155 5.0 x 0.8 5.0 x 1 PHILIPS 122 40 810 60 14 125 2.3 x 0.4 25 x 00 PHILIPS 110 20 850 200 22 284 3.5 x 0 PHILIPS 5.0 x 1 PHILIPS 250 80 851 200 25 396 5.0 X 1 PHILIPS 6.0 x 2 PHILIPS 250 105 852 200 27 313 6.0 x 2 PHILIPS 8.0 x 3 PHILIPS 255 170 903 I 250 23 342 6.0 x 0.8 2.5 x 00 PHILIPS 300 100 904 100 23 192 6.0 X 0.7 50 X 1 PHILIPS 150 60 905 140 23 232 6.0 X 0.8 6.0 X 2 PHILIPS 190 70 906 140 27 245 8.0 X 0.9 8.0 X 3 PHILIPS 205 115 907 200 23 292 6.0 X 0.8 6.0 X 2 PHILIPS 250 95

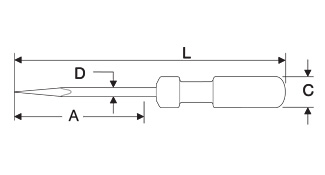

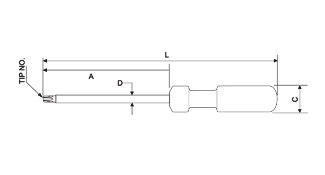

Torx Screw Drivers

The blade is made from high grade silicon manganese steel. It is full hardened & tempered withstand high torque requirements and magnetized to lift screws etc. from confined spares or to hold screw in position. It is also effectively protected against corrosion by Nickel Chrome plating.

-

PROD. NO. A C D L WT.GMS T – 5 75 17 3.0 140 22 T – 5L 150 17 3.0 215 28 T – 6 75 17 3.0 150 22 T – 6L 150 17 3.0 225 28 T – 8 75 17 3.5 150 25 T – 8L 150 17 3.5 225 35 T – 10 75 17 3.5 150 25 T – 10L 150 17 3.5 225 35 T – 15 75 22 5.0 161 50 T – 15L 150 22 5.0 236 60 T – 20 100 22 5.0 186 55 T – 20L 200 22 5.0 286 65 T – 25 100 26 6.0 198 90 T – 25 L 200 26 6.0 298 105 T – 30 100 26 6.0 198 90 T – 30 L 200 26 6.0 298 105 T – 40 125 28 8.0 230 120 T – 40 L 200 28 8.0 305 150

Striking Screw Drivers

-

PROD. NO. A C D L WT.GMS OGS 8210 75 17 3.0 140 22 OGS 8260 150 17 3.0 215 28 OGS 1200 75 17 3.0 150 22 OGS 1250 150 17 3.0 225 28

Precision Screw Driver Set

-

PROD. NO. CONTENTS PSFP6 Precision Screw Driver Set (6 Pcs.)

(Containing flat 1.4mm, 2.0mm

Tip 2.4mm, 3.0mm & PHILIPS Tip no. 1&2)PSF6 Precision Screw Driver Set (6 Pcs.)

(Containing flat 0.8mm, 1.0mm

Tip 1.2mm, 1.6mm & 2.0mm & 2.5mm)PST6 Precision Screw Driver Set (6 Pcs.)

(Containing flat 1.4mm, 2.0mm)

Screw Driver Sets with Neon Bulbs

-

PROD. NO. CONTENTS NO OF BLADES 802 6.0 x 0.8, 3.5 x 0.5, PHILIPS 0,Square Poker, PHILIPS 1 5 812 6.0 x 0.8, 3.5 x 0.5, PHILIPS 0,Square Poker, PHILIPS 1 5 831 3.5 x 0.5, 4.3 x 0.6, 6 x 0.8, PHILIPS No. 1,PHILIPS No. 2, Poker Round, Poker Sq., Wooden Screw Type 8 840 6.0x0.8, 3.5x0.5, PHILIPS 0, Square Poker. PHILIPS 1 + Extension Road 6

Screw Driver with Neon Bulbs

Generally Conforming to IS 5579-1985

TAPARIA® Line Tester has high quality blade and cellulose acetate plastic Handle.Fully insulated blade ensures shock proof working. Distinct glow of Neon lamp identifies line ‘live’. Features a clip for safe carrying in pocket. Available in several sizes.

-

PROD. NO. HANDLE A TIP SIZE

B x TC D L WT.GMS 813 Yellow 55 3.5 x 0.4 17 6 130 25 814 Green 60 3.5 x 0.5 14 6 125 20 815 Green 100 3.5 x 0.5 18 6 180 35 816 Yellow 95 3.5 x 0.5 17 6 170 35 818 Yellow 60 SQ.POKER 14 6 125 20 873 Yellow 114 4.0 X 0.6 18 4 200 30

Multipurpose Digital Line Tester

To Measure 12V to 220V AC and DC Voltage. To locate break point of an insulated wire. To check flow of current in an insulated wire from outside.

-

PROD. NO. A B x T C L WT.GMS MDT 81 20 3.0 x 0.5 18 130 17 MDTN 82

(With Neon Bulb)20 3.0 X 0.5 17 120 14

Three in one Tester

Consists of a TAPARIA® Line Tester and an easily attachable extension cord with a Test Probe. Easily checks ‘live’ or Neutral wire, continuity or break in circuit. Identifies two different phases. Ideal for domestic use.

In phase line where board is open lamp hold will not work at 440 V bulb will be damaged where as 3 in 1 tester will indicate this different phase of 440 V by glowing more brightly.

If we get phase from one wire and at the other end bulb does not glow indicate wires are from same phase.

-

PROD. NO. Handle TIP SIZE

B x TC L WT.GMS 817 – 1413 Ext. Cord. Yellow 3.5 x 0.5 14 1200 65

Screw Driver Kits (Hanging Pouch)

-

PROD.NO CONTENTS 1013 Consisting of 8 Screw Driver 713, 922, 725, 828, 912, 712, 937, P5 861 75

Screw Driver Kits (Blister Packaging)

-

PROD.NO CONTENTS 1014 Consisting of 7 Screw Drivers 824, P5 861 75, P6 862 100, 913, 925, 935, 814 1017 Consisting of 5 PHILIPS Screw Driver P3 859 50,P3 860 60, P5861 75, P6 862 100, P8 863 200